### Electro Discharge Machining: A Deep Dive into the Spark of Precision

**Introduction:**

Electro Discharge Machining (EDM), often referred to as spark machining or spark eroding, is a revolutionary manufacturing process that uses electrical discharges to shape and create highly precise components. Renowned for its ability to machine hard metals and intricate geometries, EDM has become an essential tool in industries such as aerospace, automotive, and medical devices. This article takes a deep dive into the principles, applications, and advantages of EDM, showcasing why it’s considered the “spark” of precision in modern manufacturing.

—

### 1. **What is Electro Discharge Machining?**

EDM is a non-conventional machining process that removes material from a workpiece using electrical discharges (sparks). Unlike traditional machining methods, which rely on physical contact between the tool and the material, EDM uses controlled electrical sparks to vaporize or erode material. This makes it ideal for machining materials that are too hard or complex for conventional methods.

**Key Components of EDM:**

– **Electrode:** A tool that generates the electrical spark.

– **Workpiece:** The material to be machined, which must be electrically conductive.

– **Dielectric Fluid:** A liquid medium that controls the spark and flushes away eroded material.

– **Power Supply:** Provides the electrical energy needed to generate the spark.

—

### 2. **How Does EDM Work?**

EDM operates on a simple principle: electrical discharges occur between the electrode and the workpiece when they are brought close together in a dielectric medium. These discharges generate intense heat, which melts or vaporizes the material in microscopic amounts. The dielectric fluid cools the area and removes the eroded material, leaving behind a precisely machined surface.

**The EDM Process:**

1. The electrode and workpiece are positioned close to each other but do not make physical contact.

2. A pulsed electrical current creates a series of sparks.

3. Each spark generates temperatures of up to 12,000°C, melting or vaporizing the material.

4. The dielectric fluid cools the area and flushes away debris, preventing short circuits.

This process repeats thousands of times per second, allowing for precise material removal.

—

### 3. **Types of EDM**

EDM is versatile and comes in various forms to suit different applications. The two primary types are:

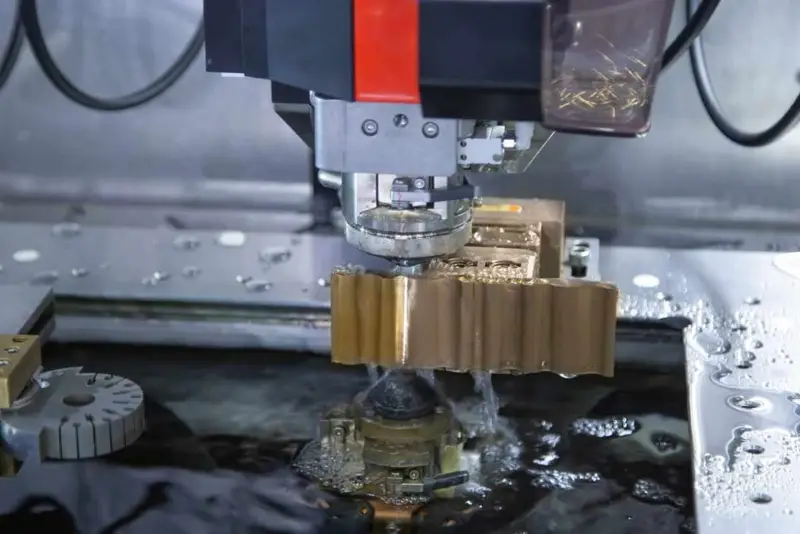

#### **a) Die-Sinking EDM**

In this method, the electrode is shaped like the desired cavity or mold. As the sparks erode the material, the workpiece takes on the shape of the electrode. Die-sinking EDM is ideal for creating complex molds, dies, and cavities in industries like injection molding and aerospace.

**Applications of Die-Sinking EDM:**

– Manufacturing intricate molds for plastic injection.

– Creating dies for forging and stamping processes.

– Producing components with high surface finish requirements.

#### **b) Wire EDM**

Wire EDM uses a thin, electrically charged wire as the electrode to cut through materials. It works like a precision saw, slicing through metals without physical contact. Wire EDM is perfect for producing detailed parts and intricate geometries.

charged wire as the electrode to cut through materials. It works like a precision saw, slicing through metals without physical contact. Wire EDM is perfect for producing detailed parts and intricate geometries.

**Applications of Wire EDM:**

– Cutting intricate profiles in hard metals like titanium and carbide.

– Machining components for medical devices and electronics.

– Producing prototypes with tight tolerances.

—

### 4. **Advantages of EDM**

EDM offers numerous advantages that make it a preferred choice for precision manufacturing:

#### **a) Ability to Machine Hard Materials**

EDM can easily machine materials like tungsten, titanium, and hardened steel, which are challenging to work with using traditional methods.

#### **b) High Precision and Accuracy**

EDM’s non-contact nature ensures minimal distortion, allowing for the creation of intricate designs with tolerances as tight as 0.002 mm.

#### **c) Complex Geometries**

EDM can produce sharp corners, narrow slots, and intricate shapes that are nearly impossible to achieve with conventional machining.

#### **d) Excellent Surface Finish**

The process leaves a smooth, high-quality surface finish, reducing the need for additional polishing or finishing operations.

#### **e) No Physical Contact**

Because there is no physical contact between the electrode and the workpiece, there’s no risk of mechanical stress or deformation.

—

### 5. **Limitations of EDM**

While EDM is highly versatile, it does have some limitations:

– **Material Requirements:** EDM only works with electrically conductive materials, limiting its application to metals and certain composites.

– **Slow Material Removal Rate:** Compared to traditional machining methods, EDM can be slower, particularly for large-scale operations.

– **Electrode Wear:** The electrode gradually wears out during the process, requiring frequent replacement for prolonged operations.

– **High Operational Costs:** EDM equipment and dielectric fluids can be expensive, especially for small-scale operations.

—

### 6. **Applications Across Industries**

EDM is widely used in various industries where precision and quality are paramount:

#### **Aerospace**

– Manufacturing turbine blades and engine components.

– Creating intricate molds for lightweight yet durable materials.

#### **Automotive**

– Producing injection molds for car parts.

– Machining components for engines and transmissions.

#### **Medical Devices**

– Fabricating surgical instruments with tight tolerances.

– Producing custom implants and prosthetics.

#### **Electronics**

– Cutting intricate parts for semiconductors and circuit boards.

– Creating precision components for microelectronics.

—

### 7. **The Future of EDM**

As industries demand higher precision and efficiency, EDM technology continues to evolve. Innovations such as additive EDM, advanced dielectric fluids, and automation are making the process faster and more sustainable. Moreover, the integration of EDM with technologies like 3D printing and AI is opening up new possibilities for complex manufacturing.

**Key Trends:**

– **Automation:** Robotic systems are being integrated with EDM machines to enhance productivity and consistency.

– **Green EDM:** Environmentally friendly dielectric fluids and energy-efficient designs are reducing the environmental impact of EDM.

– **Hybrid Manufacturing:** Combining EDM with additive manufacturing is enabling the creation of intricate designs that were previously impossible.

—

### Conclusion: The Spark of Precision

Electro Discharge Machining stands as a testament to the power of innovation in manufacturing. Its ability to handle complex geometries, machine hard materials, and deliver unmatched precision makes it indispensable in industries where quality is non-negotiable. While it comes with its challenges, the benefits of EDM far outweigh its limitations, and its continuous evolution promises a bright future for advanced manufacturing. Whether you’re crafting a tiny medical implant or a massive aerospace component, EDM remains the ultimate tool for precision and excellence.

—

Let me know if you’d like to refine any section or add specific details!